What is Zamak?

What is Zamak? What are its Components?

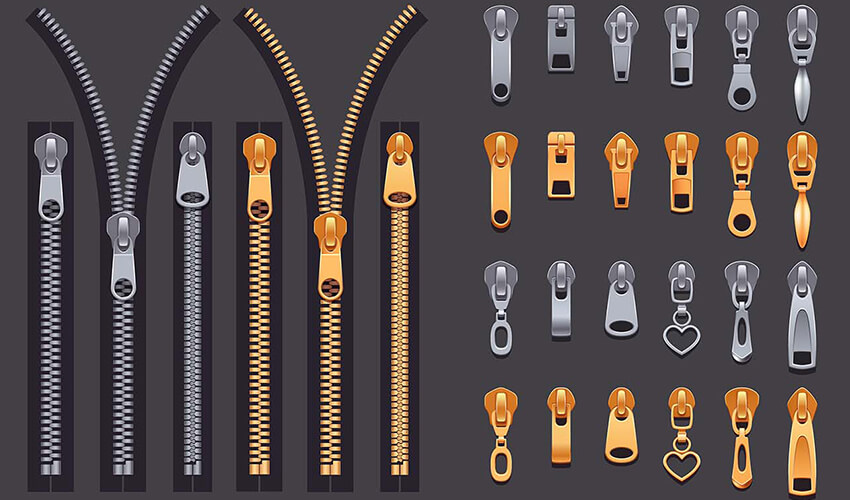

Indeed, those who are unfamiliar with Zamak do not know frequently about its properties. It is preferred to be used in many various products. This material is disposed of in many areas such as automotive, furniture, household appliances, toys, clothing, etc. However, it is the more preferred and used material in die casting. Zamak, a Zinc alloy, consists of combining Magnesium, Copper, and Aluminum elements with zinc. After it was developed in the USA in 1929, Zamak has been using in many areas and the production of zipper slider parts. Due to its properties, it is termed a versatile and valuable alloy.

What are Zamak’s Components?

Zamak does not identify as a metal. Therefore, Zamak consists of the German initials of its components. Zamak elements are as follows;

- Zink,

- Aluminium,

- Magnesium,

- Kupfer

What are the Zamak Properties?

The main advantages of Zamak material, which is known to maintain many benefits, especially strong performance, can be summarized as follows;

- It is more robust than other materials.

- It has durability for a long time.

- It is resistant to corrosion.

- It is an easily processable material.

- It is a cost-effective material.

- It provides minimum consumption in energy.

- Its color does not change.

These are one of the essential advantages of this material on the user's side.

What are the Disadvantages of Zamak Material?

Among the disadvantages of this material, the rough surface quality is placed on the top. Another significant disadvantage is that many casting errors can be seen.

Why is Zamak Using in the Zipper Slider?

With the properties of Zamak material, it is preferred to produce zipper slider parts, especially sliders. Zamak is highly preferred because it is resistant to corrosion. An intense force is affected in the opening or closing process. Because pressure is operated in the opening or closing process too much. When the teeth do not work clearly, the force on the slider could be more than usual. Therefore, non-durable metals can be damaged. In addition, because of the high resistance to corrosion, no change in the metal structure never sees. It makes the metal more robust and more durable.

TRYEA